Gallagher Print House’s Sustainability efforts – From reducing plastic waste to repurposing materials

Sunday, 16 February, 2025

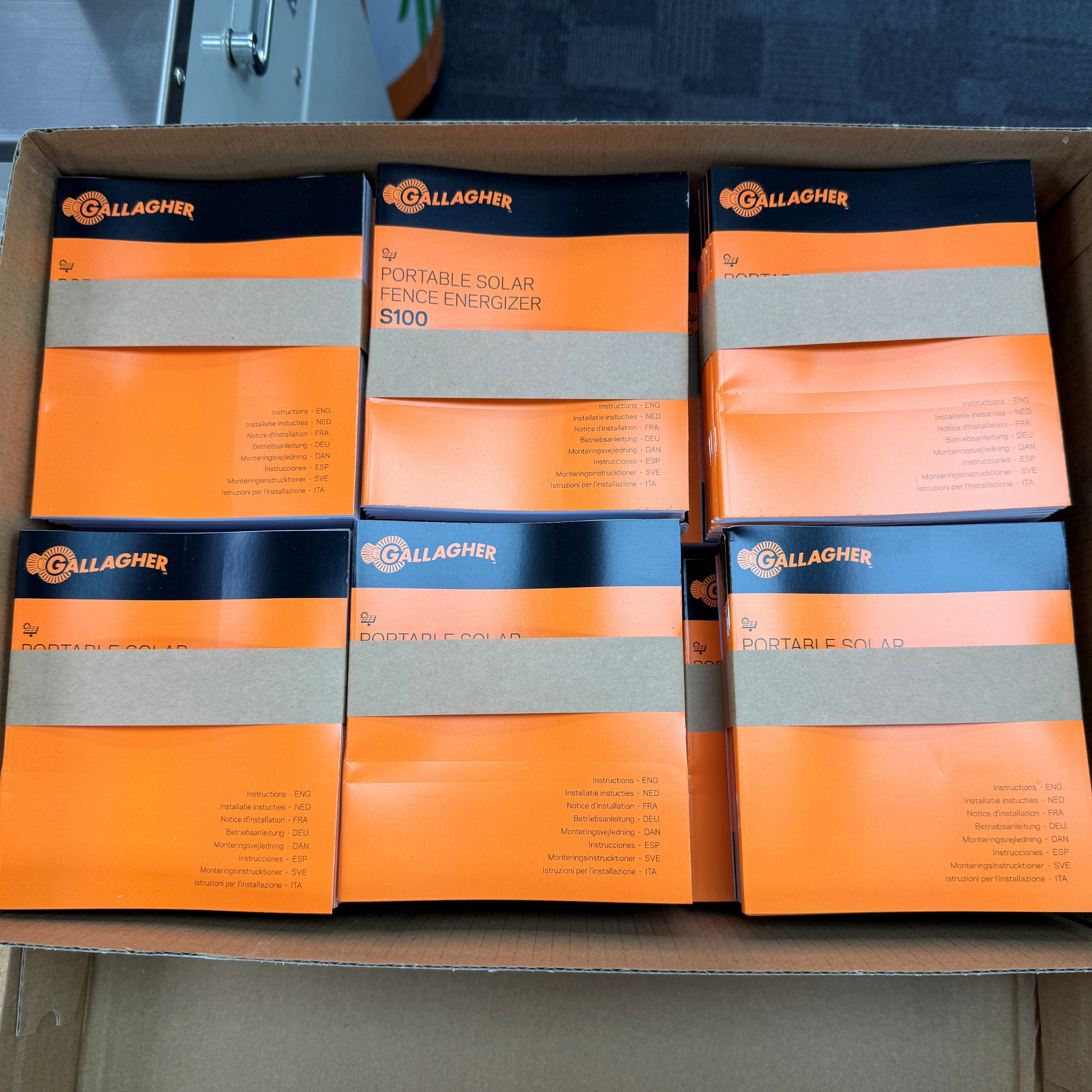

Did you know we have our very own in-house printing team at our Hamilton headquarters? Known as the Print House, this team not only produces printed material used in our products but is also taking steps to reduce waste and operate more sustainably.

“As well as being responsible for most of the printed material and labels used in and on our finished products, Print House works closely with our marketing teams to produce signage for stores and showcases for Fieldays. We also create materials for our Group Communications team, including posters, pull-up banners, and signs,” Print House Manager Steve Brown says.

In recent years, Print House has introduced several initiatives to minimize its environmental impact, particularly focusing on reducing plastic waste.

“I believe everyone should work to reduce plastic in the environment, and every little bit helps. Even the small steps we’ve taken here add up, and we’re always looking for ways to further reduce our plastic footprint,” says Steve.

One initiative is the introduction of a paper strap machine, which has significantly reduced the need for rubber bands to wrap products.

“Rubber bands are gone, and the products used internally are also no longer shrink-wrapped in plastic. This has created a 75% reduction in plastic waste from rubber bands and shrink wrap in the Print House. It also minimises waste caused by product damage when rubber bands are applied and removed.”

The Print House has also found innovative ways to repurpose materials that might otherwise go to waste. Wide-format waste cardboard rolls are now being cut into pieces to wrap labels, eliminating the need to order small cardboard rolls for this purpose.

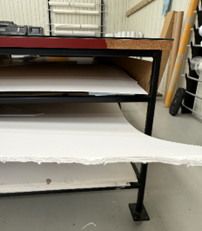

Sustainability is also being considered in the choice of materials.

“Foam sheets we’ve used in the past have been replaced with convert paper board sheets, which are fully recyclable. Stacked paper mimics the appearance of foam boards but is made entirely from recyclable paper, reducing our reliance on plastic-based foam,” Steve explains.

In addition, Print House has begun transitioning to more environmentally friendly printing products.

“Nevertear, a plastic product used for printing, is being replaced with Eco Lite, which uses 40% less plastic while retaining the same durability. We also ensure all ink cartridges are stored in recycled Fujifilm boxes until they’re collected and repurposed by Fujifilm.”

“Cardboard boxes that go to manufacturing are brought back to be reused. We do regular paper stocktaking to ensure that only what’s required is ordered, ensuring no extra stock waste.”

Looking ahead, Steve acknowledges there’s still room for improvement.

“One area we’re eager to work on is sourcing materials for our wide-format and label printing machines that don’t use plastic liners. As technology advances, I’m sure there will be paper liners on the horizon.”

We’re proud that our Print House team continues to demonstrate their commitment to reducing waste and contributing to a more sustainable future.

If you would like to read more about our sustainability efforts, please see our sustainability page here.